Winter solstice is but a few days away but we’ve been having winter weather for some time now. Our first snow in Macomb was around November 16th. There’s been lots of snow up in Santa Clara and the Adirondacks in general this autumn. Now that it’s mid December, the snow doesn’t seem like anything but fairly normal. A cold snap brought some recent single digit weather and even some negative temperatures. -8 degrees in Santa Clara one night! Brrr!

Hunting season went by quicker than expected and we never saw any bucks during rifle season. I sat in the different tree stands we had built but not even any does ever came close. The deer seemed to move about a lot. Some nights there would be a couple in the meadow by the barn after dark. Zane hunted some during rifle season but didn’t see anything either. I still hunted some as well. Wandering around helped me try to figure out where the deer were staying.

We got a pop up hunting blind to use in areas where we had no tree stands. We used it some but I think it’s a little better suited to early season hunting. We never saw any deer while sitting in it. I sat in it one evening as we got hit by some heavy freezing rain. It was nice to be out of that! I later moved it to a new spot right before the season ended but never saw anything there either. We will experiment with it more next year. It’s got potential.

As we got closer to the end of rifle season, Zane and I did some deer drives. We pushed out a few deer but neither of us got a shot. Some fresh snow the final weekend of rifle made for some decent tracking conditions. That was fun! It was easy to identify where the deer were moving.

The weather turned pretty crappy the final weekend of rifle season and the snow was starting to add up. I wandered around some in the wind and snow hoping to get lucky. It was not to be. But we still had late muzzleloader season for one week to try and fill unused tags. It had turned rather cold and there were many flocks of geese suddenly moving south. You could easily spot several flocks at any given time for a couple days. It was obvious that things were moving closer to winter.

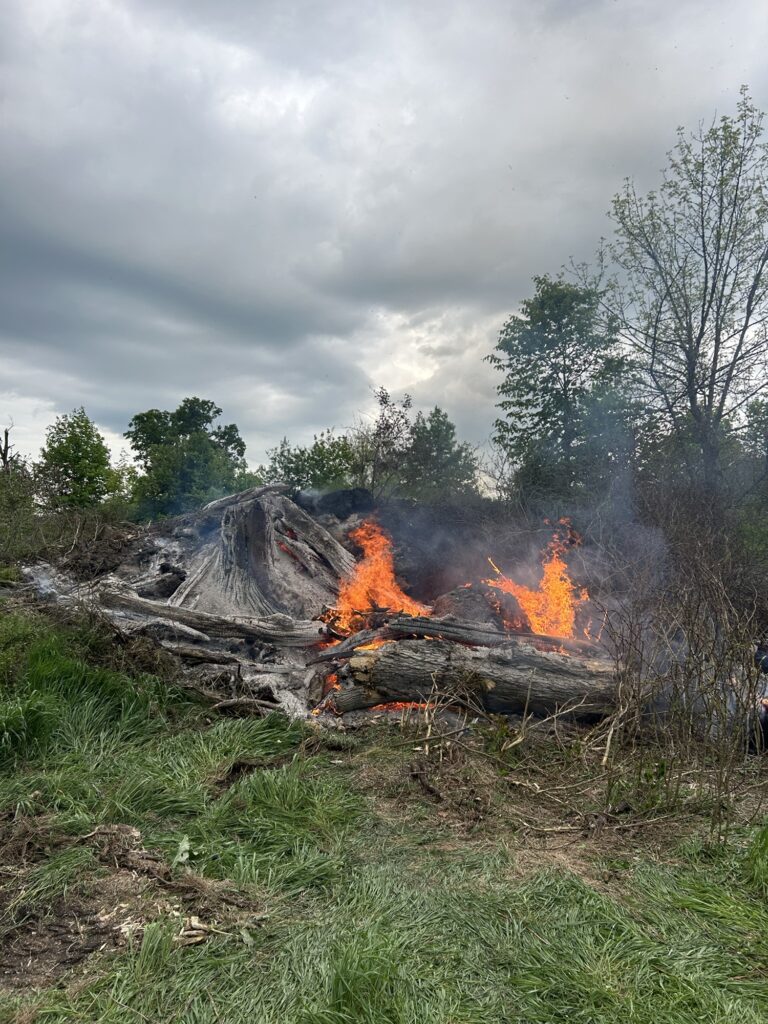

During all this time I was busy getting some wood cut and cleaning up some fallen die off maples that kept dropping limbs into the meadow below the Gap Ridge. They were a bit of an eyesore from the cabin windows and I was tired of looking at them. Not to mention that there was some nice dead red elm to cut in the same area. I decided to make a small landing on the edge of the meadow after cutting down the brush that had overtaken the old fence row. I built a large brush pile and added sections of rotten maple logs to it using the tractor. I had a great fire one night and kept it going for a couple days. Fire is the best way to ditch old logs and brush.

I had done something similar once near that location and had called my work “Operation Burn Clear”. It’s a good title for some goals Zane and I have for reclaiming the meadow edges. It’s going to take some time that’s for sure.

Gathering firewood is never a wasted effort and we always end up needing it. I have gone through quite a bit of firewood in the cabin this fall actually. I have brought a few loads of wood to Amy’s this fall. There’s a wood stove and a wood boiler in the basement so it has been a nice complement to the 25 cord that came with the house back in September. I usually top off my supply in the cabin when I’m getting a truck load of wood cut up. I like the smaller pieces of super dry red elm for the small wood stove that heats it.

There’s no shortage of dead trees on the farm to attempt to get cleaned up. I don’t think we could get caught up unless we started using much more. So it’s pick and choose for the best ascetics. After the burn bans of the spring,summer, and early fall, it was nice to be able to burn.

I was lucky to get a load of wood cut and hauled before last week’s big snow storm that started Tuesday and went into Wednesday. By Thursday I needed to plow the driveway out at the farm for the first time this fall. There was so much snow that the Honda utv could barely plow through. Luckily I had some previous trails to follow in the prior snow that I managed to reopen. Good thing it has four wheel drive! I tooled around looking for deer sign but it was absent near the barn and up beyond the Gap Ridge. NP. I’d go try somewhere else.

I got my muzzleloader out and fired a couple primers to temper the barrel before loading it. I didn’t fire it as I didn’t want to dirty the barrel. Something I would live to regret! I sat last that night up in the hunting blind after spinning the way up into the woods with the Honda to reach a place to park nearby. It was bitter cold and there were no fresh deer tracks anywhere near. It was time for a new strategy I decided. On Friday I would press hard for “The Mountain”. It would be difficult with almost knee deep snow but the deer had been hanging around in the meadows near the base of it. The plan was simple: wade the deep snow slowly and hit the high ledges for the view if nothing else. It’s something I like to do usually,minus the deep snow. It was the best idea that I could come up and what I had been trying hadn’t worked to date.Time was running out! Deer season closed at sunset on Sunday night!

Friday dawned cold and clear with mostly clear, cerulean skies. As the sun climbed higher so did the temperature. It was a fine day for hunting! Much better than other recent ones of falling rain,snow, and blowing winds. The plan was simple. Carry a survival pack with food,water, fire starting kit, knife, etc. plus extra speed loaders for the gun. They are super handy as they contain everything you need to unload for one shot. I also would wear micro spikes for better traction after a test proved that they were fairly silent in the deep snow. I chose a mid morning start to give myself plenty of time before dark to complete my trek.

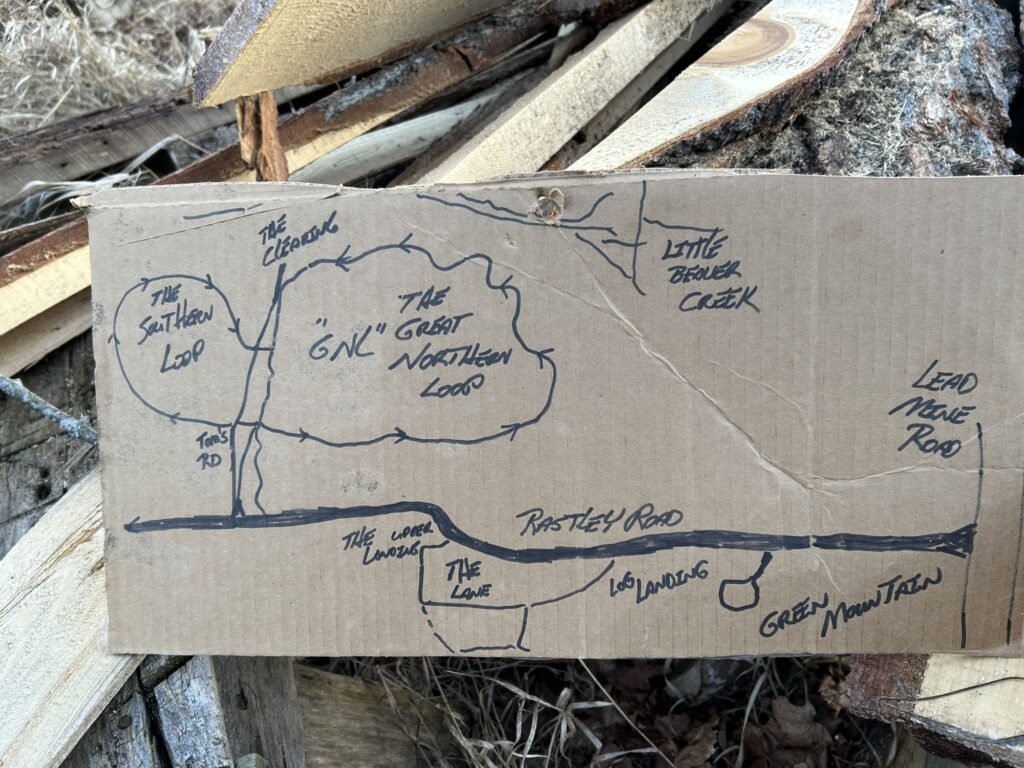

I walked the road until I reached the state land that would lead me to the Mountain. If you follow my writing then you know about the high rocky ridge that sits above Beaver Creek is what the Washburn family calls “The Mountain”. It is the highest place around and a great place to catch a view of the surrounding countryside. And sometimes there are deer to be found! Although I have never bagged one while hunting there.

It was difficult walking in the deep snow but I took my time. Falling with the gun would be bad anytime but worse in the snow. Luckily my muzzleloader has a nice sling so I put it over my neck so my hands were free. This helped me wade up to the first rocky outcropping that I had named “ The Low Point” many years ago. There’s a great view of the farm meadows there and even our big red barn is visible. I hung out for a bit to catch my breath and enjoyed the somewhat panoramic vista. Well worth the effort to get there!

I left the Low Point and made my way towards my next destination the “Mid Point”. It’s another great viewing area also with mostly panoramic sights in all directions. It was the destination Zane and I chose last Xmas Eve for our celebration fire. We hope to return this Xmas Eve to continue our newest adventure tradition for year three. The first year we had our fire at the Low Point. These experiences may be in an old blog post. If not then I had better write one!

While walking towards the Mid Point I came across a single set of partially snowed in deer tracks. Not terribly exciting really. But encouraging to a degree. Up on the Mid Point I once again caught my breath and enjoyed the views. Off to the east of where I stood, I saw what looked like deer tracks so I went to investigate slowly and quietly in the deep powder snow. I moved almost ghostlike I felt. I held my muzzleloader in my hands when I reached the tracks and realized that they were very fresh! But where were the deer?

I moved towards the edge of a ledge to get a better look. I could see deer tracks below me. A flash of movement caught my eye and a deer came into sight from the left of me. Unbelievably close! A mere 30’ away! And I suddenly realized it was a buck! It stopped and turned towards me but it was like I was invisible. Time seemed to stand still as I stood unmoving from my high tactical advantage point.The buck turned and continued walked parallel a long a flat section of another ledge below me. I popped my scope lenses cover and pulled back my hammer just in time as the buck stopped for a second. He was in my crosshairs just 40’ from me when I pulled the trigger. What happened next played out in slow motion but not for long!

When I pulled the trigger my muzzleloader made a fizzling sound like a dud Roman candle instead of the loud bang I expected. There was a tiny puff of smoke and no recoil. The sound alerted the buck and he ran down the face of the ledge with mighty leaps and gave a couple warning snorts to his companions. Doe’s from his harem I believe but I never saw them.

I stood in shock and total disbelief! Disappointment washed over me like a wave. A misfire had happened apparently. But was my weapon clear? I quickly pulled my breach plug to find that my projectile had left the barrel. But with what velocity was the question. Had I wounded the buck after all? I made my way down to where I had last seen him but there was no blood anywhere. Not a drop. Now I was super disappointed. I had waited for this moment the entire season. Now it was gone because of equipment failure. Damp powder pellets were my best guess. Perhaps the result of condensation. I regretted not firing my gun that morning for a test shot. It would have dried the barrel and had it not fired properly I would have known. Damn the bad luck I thought as I trudged back to the cabin feeling rather defeated.

Back at the cabin I played the events over and over again in my mind. I discharged my muzzleloader and it worked perfectly. I decided to take the Honda up to retrieve the hunting blind while I decided my next strategy. I would take my gun of course. Just in case.

I got the hunting blind folded up and loaded into the Honda and started back down the trail. I had noticed some deer tracks on the way in so I slowed down to study them. There is a long valley that I could see down at one point on my way out. And suddenly I spotted a deer! It was lying down actually. Totally brown and visible on the bright,white snow. I didn’t stop the Honda but kept going down the trail to where a ridge hid the valley from view. I left the wheeler running, grabbed my gun, and creep up over the ridge. I spotted a second deer lying down but my angle was wrong. I stalked my way up the ridge a second time further down and suddenly spotted a third deer. I inched a little closer and decided that I could make the shot at the newest deer that I had spotted. A big doe but my tag was good for that. I might never get a better chance than this. I fired.

My gun performed flawlessly. The deer didn’t run and I knew right off that I had made a kill shot. For that I was grateful. And just like that my luck had changed. I still felt bad about missing the buck. ( did I really miss him in a sense?) I walked up on my fallen prey and thanked her for her sacrifice. I felt blessed for good eyesight and steady hands. And there was that moment of sadness that comes when killing a deer. But there was work to do and it was turning colder even though it was only 3 pm!

I had trouble loading the big doe even after field dressing her. With the help of a rope I got her into the back of the Honda finally. Back at the farm I hoisted her up in the warehouse and made ready to cut her up. It was getting late so I needed to set up the generator for lights. Zane came over to help and eventually the deer was skinned,trimmed, and quartered into our large cooler. The end to a day of ups and downs. But my deer hunting season was over just like that. And I took catch my breath again. My deer wouldn’t get the chance to freeze solid during the super cold night. I had made that mistake years ago once. Never again if I can help it!

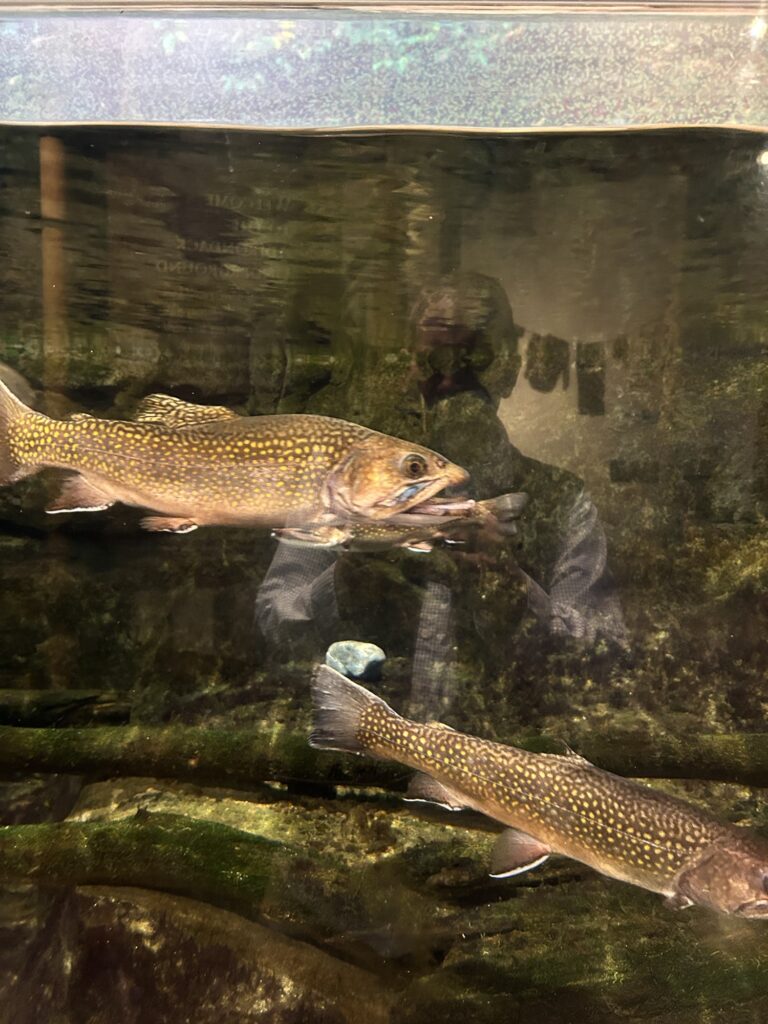

So this week I have been cutting up the deer and packaging it. I made over 30 lbs of venison burger from my big doe. We are in good shape for the winter months to come. Venison, walleye, and some morel mushrooms in the freezer. Hunting deer was something that I had given up for quite a few years actually. But I am glad that Zane got me interested in taking it back up again. It’s been quite the fall! Lots of great memories and lessons to be learned. And we sure are enjoying all the wonderful lean meat that’s super healthy!

Hunting and gathering are a big part of my rural heritage lifestyle. I’m excited to be sharing this with Zane. We have big plans for next season already! Until then we wait for what comes next. Winter will bring new adventures and new opportunities. Challenges and fun times. And maple syrup season is never too far from my thoughts. I will sit by the wood stove and enjoy maple syrup infused coffee while pondering it all. I will listen and see where my spirit energy leads me. And we’ll enjoy meals from our successful harvests from the bounties of nature. We truly are connected. And for that we are forever grateful with most humble thanks! MOONTABS! ✍️